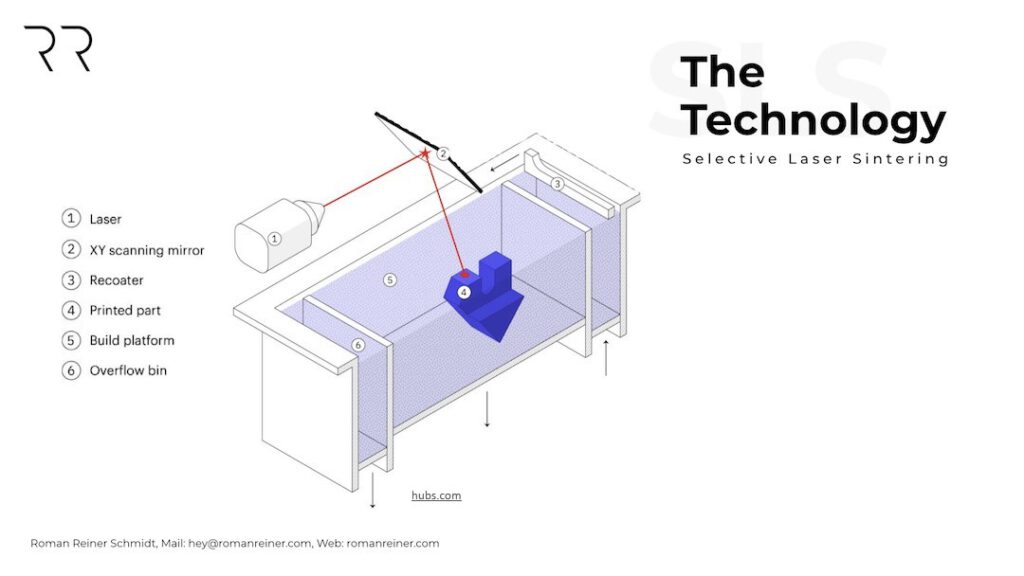

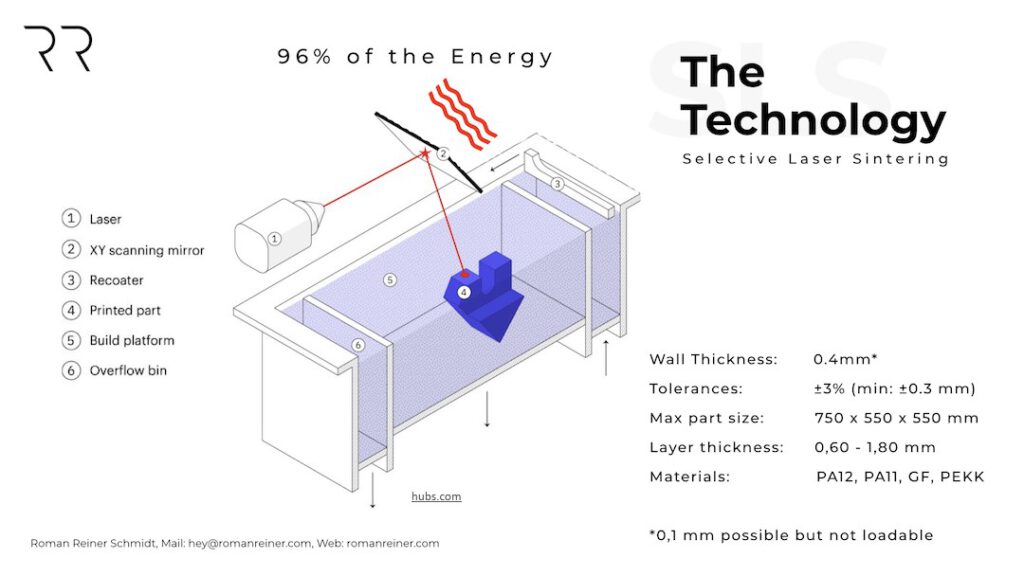

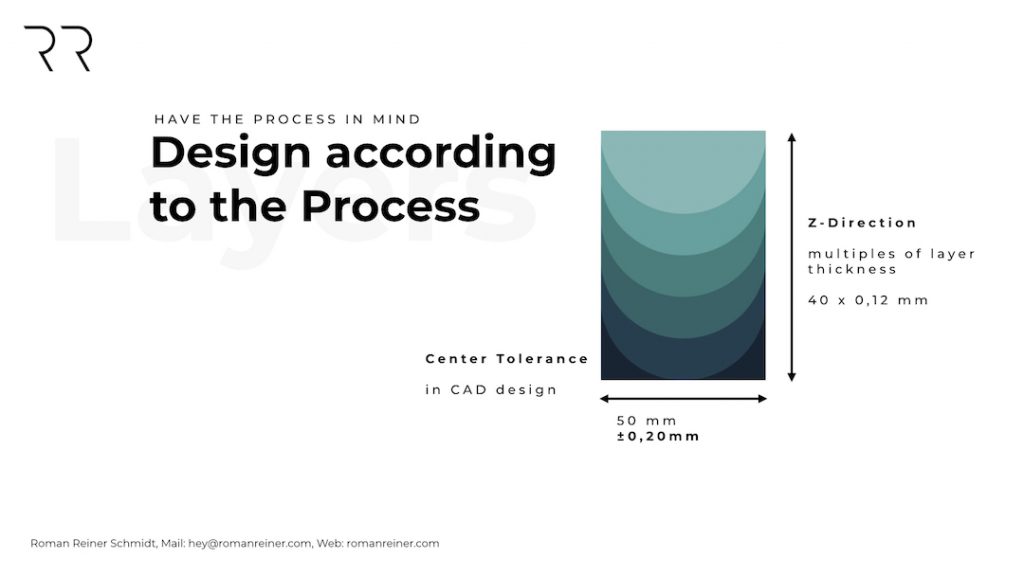

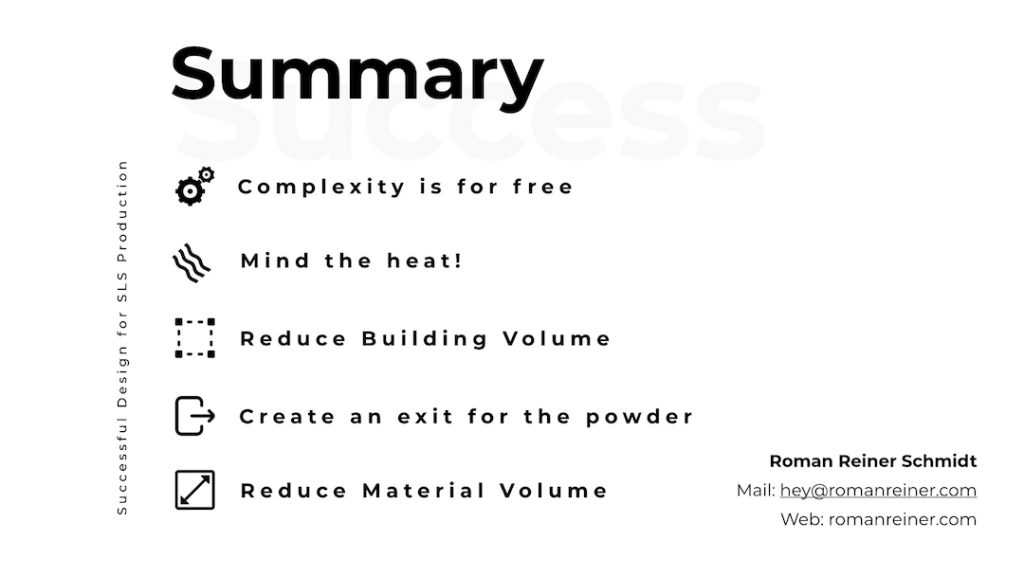

Unlocking the Full Potential of Selective-Laser-Sintering

Kommentare

Eine Antwort zu „Unlocking the Full Potential of Selective-Laser-Sintering“

-

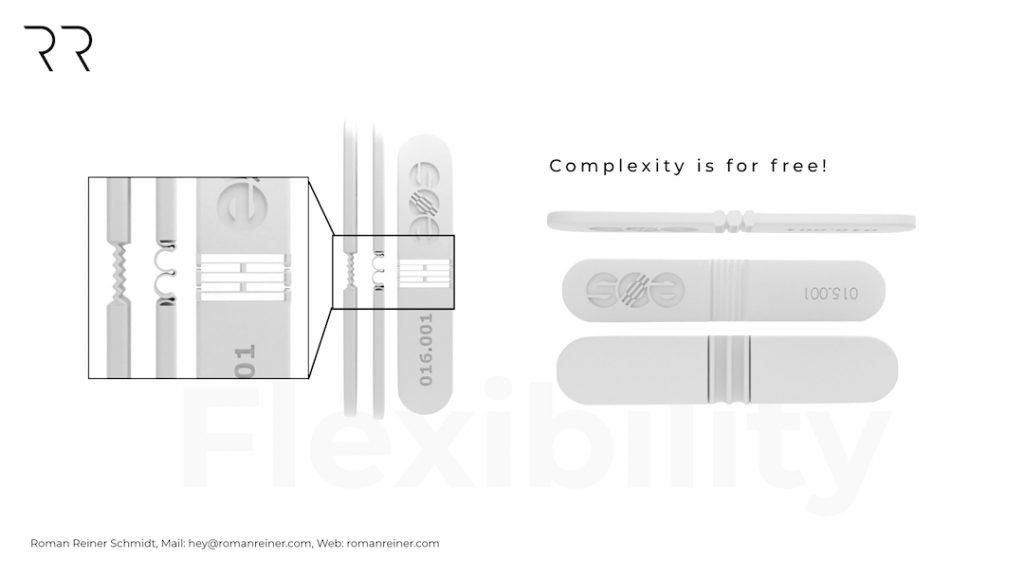

[…] I mentioned in my last post about „Unlocking the full potential of Selective-Laser-Sintering“, lattice structures bring great advantages to 3D Printing/ Additive Manufacturing. They can be used […]

Schreibe einen Kommentar